- Insight

- April 17, 2024

Innovative energy efficiency: the 3 technologies selected by STEP

The level of improvement in energy intensity during this decade (2020-2030) will determine whether the world will develop along a high, medium or low energy demand path, leading these years to be defined as “the crucial decade for energy efficiency” (Versailles Statement, 2023). To achieve the goal, innovative solutions operate on the variables of quality, quantity and sources of production.

As an Innovation Hub focused on sustainable innovation for industry, our projects over the past year have led us to focus on the latest energy efficiency technologies in line with the European guiding principle of “Energy Efficiency First.” These solutions help companies take their first steps on decarbonization paths and enable them to:

- Significantly reduce operating costs;

- Effectively manage energy in the production plant

- Achieving greater business resilience

- Gaining confidence and trust in sustainable innovation

- Do not change the production process

Our perception, considering the benefits, is that these technologies are not receiving the proper attention. For this reason, we have selected three technologies of interest to industry, described below.

We also talk about it on our Linkedin channel. Learn more!

Next Generation Power Stabilization Technology

- Emission reduction: Scope 2

- Benefits: typical energy savings are between 4% and 6% of total electricity consumption, through offsetting peaks and troughs in grid voltage up to +/-20%

- Where it applies: to the whole establishment

Power Stabilization represents an innovative and easy-to-implement technology for optimizing the energy efficiency of industrial plants. Among the various technologies that we have selected, evaluated and tested, this solution stands out clearly from traditional power quality or power factor correction systems, which many industrial realities have already experimented with, obtaining unsatisfactory results. The one validated by STEP is characterized as a next-generation technology, equipped with an algorithm for calculating energy savings certified by ENEA, which ensures excellent results and is applicable in a wide range of circumstances and sectors.

The problem

Electricity distribution in the grid is constantly subject to major alterations in frequency and voltage values, causing energy inefficiencies, machinery breakdowns and associated maintenance costs, as well as potential loss of productivity and data.

The solution

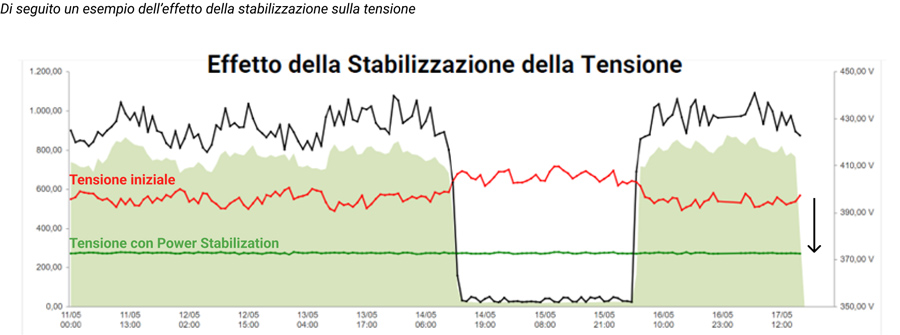

Figure 1 – Effect of voltage stabilization on a specific case

Figure 2 – Main benefits of the technology selected by STEP

The benefit environmental is proportional to energy savings: a case study carried out with one of our client companies showed that it is possible to save 300 MWh/year with this technology. Assuming an average of 0.4 kg of CO2eq put into the atmosphere per kilowatt-hour, this figure corresponds to about 120 tons of CO2eq avoided.

IoT system to maximize energy production

- Emission reduction: Scope 2

- Benefits: optimal cogenerator/trigenerator management by leveraging internal and external data analysis

- Where it applies: industrial realities with multiple energy supplies, such as cogenerators or trigenerators with photovoltaics and other sources

Among many selected and market-tested solutions, we chose this innovative IoT platform that in real time optimizes the operation of the cogenerator/trigenerator while maximizing its economic performance.

The problem

Companies that have a cogeneration or trigeneration system often do not use this asset to 100 percent of its potential, foregoing some of the value of the investment. Optimization of this asset requires the analysis of multiple data, an analysis that cannot be accomplished by the individual operator, but requires a system capable of aggregating and analyzing a large amount of data.

The solution

The technology selected by STEP is an innovative solution that monitors the energy fed into a system through CHP in real time and, by reprocessing the data collected, optimizes its performance, providing the best energy configuration for the plant.

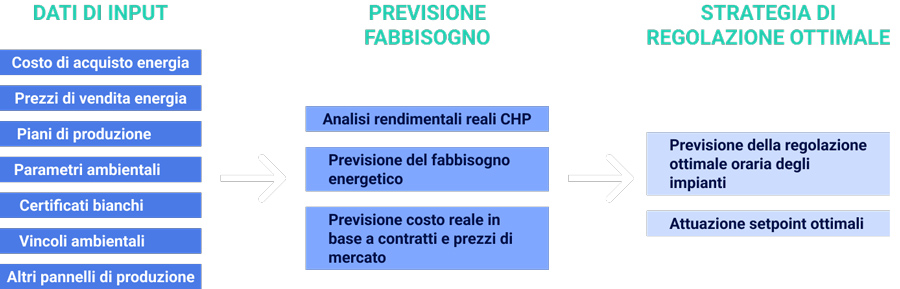

Through IoT, this solution collects data from inside and outside the company, leveraging it as a valuable resource:

- Energy purchase cost

- Energy selling prices

- Production plans

- Environmental parameters

- White certificates

- Environmental constraints

- Other production panels

The system processes the data to provide a requirement forecast, described as follows: a simulation of the real cost of energy based on contracts and the exchange, a forecast of the company’s energy costs, a forecast and final balance of accrued TEEs, an analysis of the cogenerator’s performance, and detection of anomalies for predictive maintenance.

At the end of the process, the technology provides as its final output an optimal control strategy consisting of:

- Prediction of the optimal hourly adjustment of plants

- Implementation of optimal setpoints

Figure 3 – Data analysis and processing in the technology selected by STEP

The benefits

Thanks to the Internet of Things (IoT) and Artificial Intelligence (AI), people are managing their assets intelligently, resulting in significant economic savings on energy expenses that, for industries, average between 8 percent and 15 percent.

Figure 4 – Main benefits of the technology selected by STEP

New technologies for more efficient nitrogen management

- Emission reduction: Scope 1

- Benefits: abatement of methane use by electrifying thermal power generation while producing cooling energy

- Where it applies: MCR processes, sterilization, desulfurization and cooling

Nitrogen is a gas with wide application in various industries, from food to chemical, which use it for:

- Avoiding oxidation

- Preventing the formation of fire or explosion

- Technical gas

- Creating controlled atmospheres

From many selected and market-tested solutions, considering various process specifications, we have chosen the most innovative nitrogen management solutions that meet any requirement for purity of this gas.

The benefits

The hypothetical economic savings are as high as 60 percent, considering the average value found by companies that have implemented this technology.

These innovations are applicable to any required nitrogen purity condition. I am able to provide a

high purity

so

fast

, clean,

less impactful on the environment

and with a

efficiency

energy than any other process.

Figure 5 – Main benefits of the technology selected by STEP